This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Customer

SYSTEMA is a service provider for IT solutions and supports semiconductor manufacturers in optimizing the digitization process necessary to meet the needs of the entire semiconductor value chain – from front-end wafer production to back-end assembly and testing. It mainly involves manufacturing systems integration, consulting, and building dedicated automation solutions.

One of the company’s large divisions is developing semiconductor manufacturing management software, the Manufacturing Executing System (MES). Systema’s customer in this division is a Munich-based company that produces integrated circuits for 4G and 5G filters for a US processor manufacturer.

Challenge

The client needed qualified specialists to assist with manufacturing automation projects for a client in the semiconductor industry. To accomplish this, he needed high-end Java developers who had experience with legacy code and could help with the transition to newer technologies. Systema decided to outsource project work to VM developers, because it needed both high-end engineers who fit well with Systema’s spirit and enterprise culture and speak German. Moreover, this gives the necessary flexibility when a project at different stages requires a variable number of programmers.

The main objective is to extend the MES system of our customer to fit modern semi-manufacturing demands, and automation standards provide an automation layer to interact with the MES and automate the equipment’s workflows for handling material and overall. It will increase productivity by reducing waste and cycle times.

The aim of the project is, among other things, to provide a stable base that would enable the automation of an increasing number of production facilities, achieving full integration and laying the foundations for a “Smart Factory”.

Solution

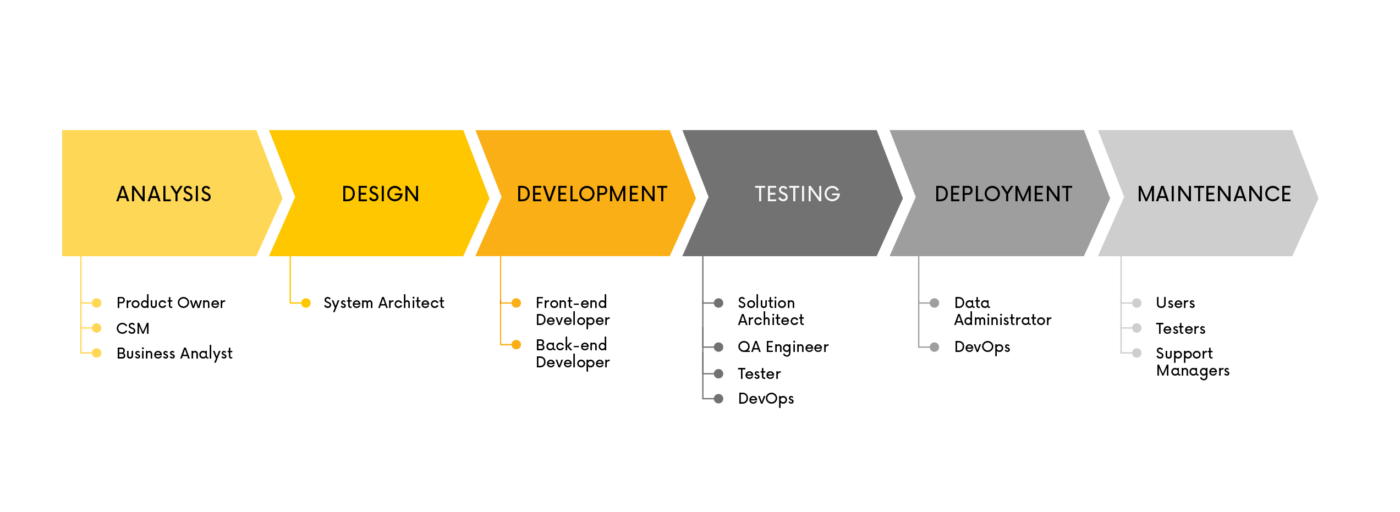

Systema decided to work with VM engineers to get support throughout the software development process, from architecture, to development, and testing. One of the first major milestones of the project was to achieve a stable software development process with a stable and efficient team of internal and external experts.

To this end, we relied on real contact between the developers and the client, who went through a classic onboarding process at the client’s premises, working regularly in hybrid mode. This form of collaboration, partly remote and partly at the client’s site, was made possible by an excellent fit for regular exchange of information, but also by the high level of experience and discipline of the VM developers, who work very well in this mode. It enabled good communication to develop plans, verify expectations, or receive regular feedback on the quality of our work. Our cooperation was divided into several stages, from consulting to development and testing at the client’s site.

Consulting role

- Describing requirements – developing a concept for an information system for the management of automated production of integrated circuits

We brought in a Business Analyst to help the client with the process. Together with the client’s team, he developed the business concept and created the Solution Design – a description of the functional requirements, including a description of the database structure and necessary components (those included and newly programmed). A record of the results of the analysis of the designed solution was made using BPMN and UML notation in modeling business processes and data structures. All documentation of the concept was generated in the Enterprise Architect (EA) tool, which is used by developers, and based on this, they perform tasks.

- Develop an agile management system

To streamline the process, we added a Scrum Master to the team, who handles the scheduled execution of tasks. Although we don’t use full Scrum here, but the entire development period is divided into monthly sprints. There are also multiple „dailies”, daily meetings of system architects, developers and project managers in a scrum-of-scrum-like manner . Tasks are run in the Azure DevOps system. VM has spearheaded the use of this type of methodology at the client, thanks to which the execution of tasks is carried out on a scheduled basis, and every day you know what has been completed.

Development – Building software to manage and automate the production process

The scope of work is spread over several stages of software development, starting with discussing requirements with the client, providing software architecture, developing source code, and testing the product. Our work is divided into three business divisions.

Project nr 1 – Dedicated SAP MES interfaces, customization of database structures, and consulting

- SAP PM-MES

Systema is extending the existing SAP PM-MES system to the manufacturing industry. Specialists from Systema and VM introduce standard solutions there, applying a customer-specific template and providing custom extensions for the customer’s needs to cover their use cases fully.

Challenge/Need

SAP is a standard that will never provide an integration interface for some manufacturers’ custom solutions. Therefore, customers needed experts for unique tailored solutions who can build custom extensions on existing landscapes.

Mileage

VM developers are responsible for custom development in one component of the SAP system for customer systems. This is because manufacturing in the semiconductor industry is highly specialized. In this case, the Client uses the SAP ERP system (widely used by many large enterprise manufacturing companies), which has a module addon SAP PM, integrated with the custom MES. SAP PM (Plant Maintenance) handles maintenance cycles of production equipment, providing maintenance counters/timers, maintenance orders, technician skill management, etc. Programmers are tasked with writing dedicated SAP interfaces, customizing database structures, and technical consulting on code basis according to the client’s current needs.

- SAP ME/MII

This is another project in our SAP department, where our developers work in this area together with different teams on different programs, .using their knowledge and extensive experience.

Challenge

Variety of production processes requires custom automations of production processes and customization of standard SAP functions like automatic components assembly in the system, labor collection, routings and reaction on production non-conformity codes. Different manufacturing types require different equipment integration, different data in communication between other SAP systems like SAP EMW or even 3-rd party systems using standard IDOC/RFC or web services. One of the main objectives often also is the creation of highly customized POD (Production Operator Dashboards) or Reports for high level analysis of KPIs .

Mileage

In this project we use JavaScript (SAP UI5) for the front end, Java SDK for the backend, and the third part is created by MAI, a blockchain software (we flip ready-made functions and customize them, combining them into algorithms).

The SAP MES (Manufacturing Execution Suite) project includes the following objects:

- SAP ME (Manufacturing Execution)

– Management AND control of all processes on the production floor based on ERP enterprise management specifications.

– ME records all information about the manufactured product during the production process, so it can be said that it is the basis of digital twin.

- SAP MII (Manufacturing Integration and Intelligence)

– The technical foundation layer of MES.

– Integration with various systems

– Ease of implementation of new functionalities

- SAP MEINT (Manufacturing Execution ERP Integration)

– Facilitates communication between SAP ERP AND SAP ME through the use e.g XSLT

– Communication methods:

SAP ERO->SAP ME: Idoc->XML

SAP ME->SAP ERP:XML->BAPI / RFC-Call

- SAP PCo (Plant Connectivity)

– PCo enables you to communicate using a language that is understood by machines and their control systems (PLCs).

– Control of machines by providing and executing actions

– Requests for current data from the machine

Result

Systema works with VM developers using their knowledge and extensive experience. Depending on the project requirements, the right specialists are matched.

Project nr 2 – Integrating machines into the automation landscape

The next project is machine integration, where several programmers develop the automation layer that controlls the machine’s process flow and links it directly to the MES and the machine-external-system-communication-interface. It includes integrating machines into the automation landscape, consisting of two modules: EQC and EQS. The software automates the steps a machine usually needs to do for processing. The functionalities are built exclusively in the back-end, mapping machine events and commands to steps in the automation layer. They are Java applications built according to Systema’s Client Server Framework (CSFW), and VM developers apply them to specific manufacturing equipments.

Challenge

Machines are not standardized. They are highly different, executing profoundly other processes, and are purpose-built. That’s already one of the challenges: machines are different, processes are other à to provide reasonable automation solutions, you need to understand many things and gain knowledge beyond software development to fulfill the requirements.

Mileage

The VM team collaborates with the client team. The process consists of the classic SDLC phases for each element: Analysis, Design, Implementation, Test. The final acceptance test takes place with the real equipment in the factory. This is usually done by process engineers with the help of software developers.

Features

The software works in a way that automates the steps a machine usually needs to do for processing. With that, the manual operation of the machine is no longer needed by an operator; all the operator has to do is start the process with the proper parameters. The functionalities are built exclusively in the back-end layer.

Project Features:

- Industry standards

- Communication via factory bus, real-time data transfer

Result

Machine integration speeds up the work of operators. Besides, we get several hundred measurement data for each wafer created in Space, MC300 or EADOS format.

Project nr 3 – Semiconductor and manufacturing management automation software

In this project our developers create products for our client’s customers in the semiconductor and manufacturing management automation software topics. The project scope includes various tasks related to the automation of the production path, such as, but not limited to, connecting systems, connecting machine software, and historization of data for audit prupose. The solution is based on microservices architecture. Two web-based user interfaces are also part of the solution – one configures the production process, and the other supervises the production flow.

Challenge

The main challenge of the project is the large amount of data that needs to be processed and correctly presented. Handling colossal data amounts between multiple components efficiently is a challenge. That’s why we took the overall micro-service architecture with Tibco MOM. Also, we are extending the existing core system. Sure, we bring in fundamentally new aspects for our customers, but nonetheless, it builds on the existing foundation.

Proceedings

The project is now in its 4th year and is still continuing. Generally, it is a distributed solution; VM developers build specific software stages. The goal is to write software that fits the standards. To achieve this, we are gathering requirements to define the interface, such as how to move between specific applications.

Features

Implementations included:

- A master data management system for setting up the system’s master data and therefore, it’s form of the fab’s “digital twin”,

- An execution engine for executing enhanced manufacturing automation scenarios during processing of goods

- Underlying framework for system integration and communication

Result

The software continues to be developed; we are developing the various parts of process automation.

Summary

As part of these complex projects we have been quick to get into the development process and help develop the Client’s systems in a shorter time. Currently, together with the Client’s team, we are working with world-class companies.

We engaged more than 20 engineers with extensive experience and high competence during the project. We had a part in developing the concept of the entire IT solution and participated in its implementation and the implementation of the pilot solution. We are currently continuing development work and are part of the client’s team that can train new employees involved in the project.

From the customer

The most impressive thing is the way they work with us. They are fully interested in our success, and associates are constantly evaluated by VM.PL. They are often already working on shortcomings before we mention it to them. Their in-house training is very effective and shows rapid improvement.

Technologies

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.